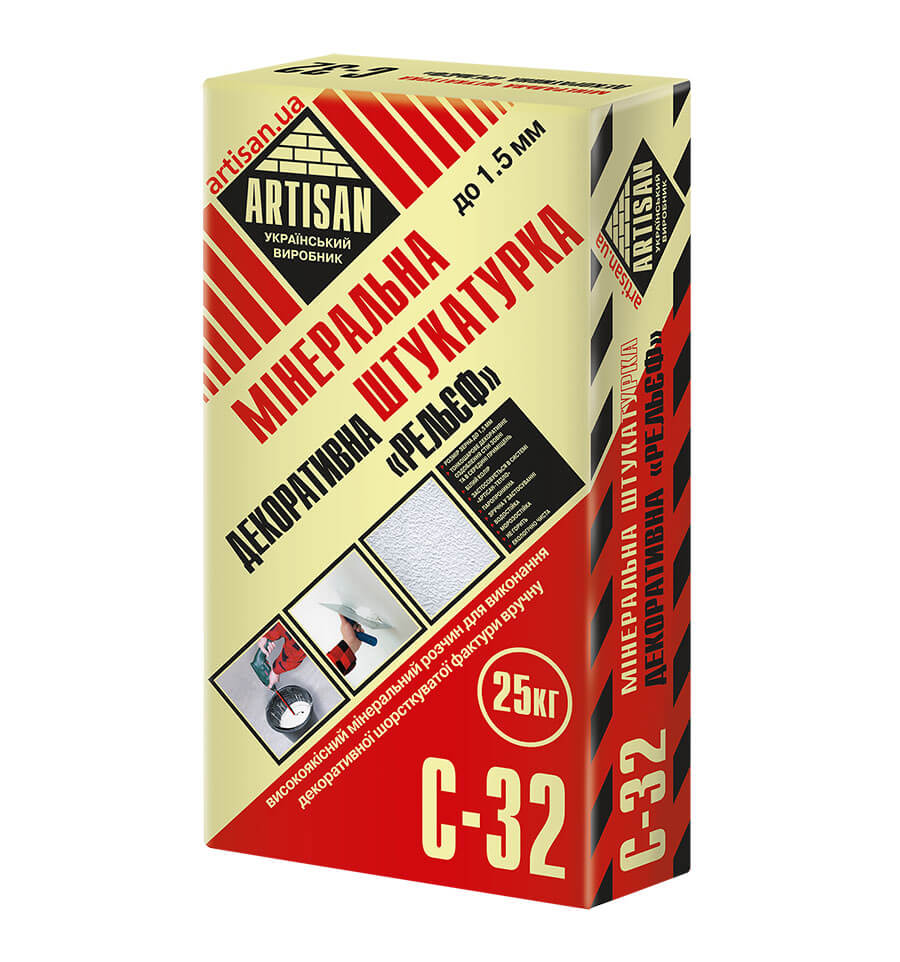

Mineral plaster «Relief» С 32

24.09.2017

Plastering leveling mortar C-39

08.10.2017Mineral plaster С 34

Mineral plaster С 34 high-quality mineral plaster mortar to carry out manually the decorative texture of “Bark beetle”

Mineral plaster С 34 high-quality mineral plaster mortar to carry out manually the decorative texture of “Bark beetle”

APPLICATION

It is used for manual external and internal decorative plastering. Can be applied to all smooth mineral substrates, such as: concrete, cement-lime plaster, gypsum board. The plaster solution can serve as a decorative layer (whiteness is not less than 85%), as the base for painting, and also as a protective layer in the “ARTISAN-WARMTH” thermal insulation system. The mineral mortar is made of marble and quartz chips to 2.5 mm. Thanks to hydrophobic additives, it has a water-repellent effect, resistant to external environmental effects.

PREPARATION OF THE SURFACE

The surface of the wall on which the plaster solution is applied should be pre-cleaned of grease, old paints, plaster exfoliations, loose substrates. All cracks, potholes and irregularities should be filled with putty. To give a roughness and to avoid lumens and stains on the plaster, the substrate should be preliminarily covered with priming paint “Artisan F-6”.

PERFORMANCE OF WORK

The mixture is poured into water and mechanically mixed until the required consistency of the solution is obtained. Leave for 5 minutes, then stir again. During the work, it is recommended to stir the solution from time to time to obtain a homogeneous mass. The plaster is applied to the prepared substrate, using a smooth stainless float. Surface is wiped or circular motions; or along the horizontal; or along the vertical until the desired texture is obtained. The grater can be either plastic or styrofoam: in any case, it should be checked on a separate site, which grater it is more convenient for a master to make an “bark beetle” effect. It should also be noted that the texturing is performed after a while – after checking the beginning of setting (the mortar mixture should not stick to the tool). The open time (the time between plastering and grouting) depends on the absorbing capacity of the substrate, the ambient temperature and the consistency of the solution. During texturing, as well as the drying of the plaster, the surface must be protected from direct sunlight, wind and of rain. It is experimentally (for this type of base and given weather) to establish the maximum surface that can be plastered in one technological cycle (application and texturing). The plaster should be docked using the “wet to wet” method, avoiding the drying of the plastered area, otherwise the joints will be visible. Technological breaks are planned with a margin (for example: in the corners and bends of buildings, under drainpipes, at the junction of color, etc.).

All recommendations are valid at a temperature of + 20 ° C and a relative humidity of 60%.

!! Under adverse weather conditions (high temperature, dry wind, direct sunlight), the time of use of the solution applied to the surface can be significantly reduced.

!! When the temperature of use of the solution decreases, the setting time increases.

When carrying out work should be guided by building codes and regulations.

The manufacturer is not responsible for improper use of the material, as well as its application in order and conditions not stipulated by the instruction.

SAFETY PRECAUTIONS

The mixture contains cement, which, when mixed with water, forms an alkali. Work should be in rubber gloves. If the solution gets into the skin or eyes, rinse them with plenty of water, if necessary, consult a doctor.

SAFETY PRECAUTIONS

The mixture contains cement, which, when mixed with water, forms an alkali. Work should be in rubber gloves. If the solution gets into the skin or eyes, rinse them with plenty of water, if necessary, consult a doctor.

EXPIRATION DATE

In dry conditions and hermetic packaging the period of storage is at least 12 months from the date of manufacture.

PACKAGING

The dry mix is packaged in bags of 25 kg.

TECHNICAL CHARACTERISTICS

Composition: mixture of white cement with mineral fillers and special additives

Amount of water for batching, ml / kg: 210-240

Time of using the mortar mixture, minutes : 60

Application temperature, ° С: from +10 to +30

Compressive strength after 28 days, MPa, not less than: 0,5

Surface Finishing : after 48 hours

Consumption, kg / m²: 2,5-2,6

GRAIN SIZE UP TO 2.5 MM

WHITE COLOR

PERFECT ON A VERTICAL SQUARE

APPLICABLE IN THE SYSTEM “ARTISAN-WARMTH”

VAPOR- PERMEABLE

CONVENIENT IN APPLICATION

WATERPROOF

FROST-RESISTANT

DOES NOT BURN

ENVIRONMENTALLY PURE

Mixture “Artisan” Ц.1.ШТ4

ДСТУ БВ.2.7-126:2011

Hygienic conclusion of the Ministry of Health of Ukraine.

You must be logged in to post a review.

Reviews

There are no reviews yet.