Self-leveling mixture for floor C 41

08.10.2017

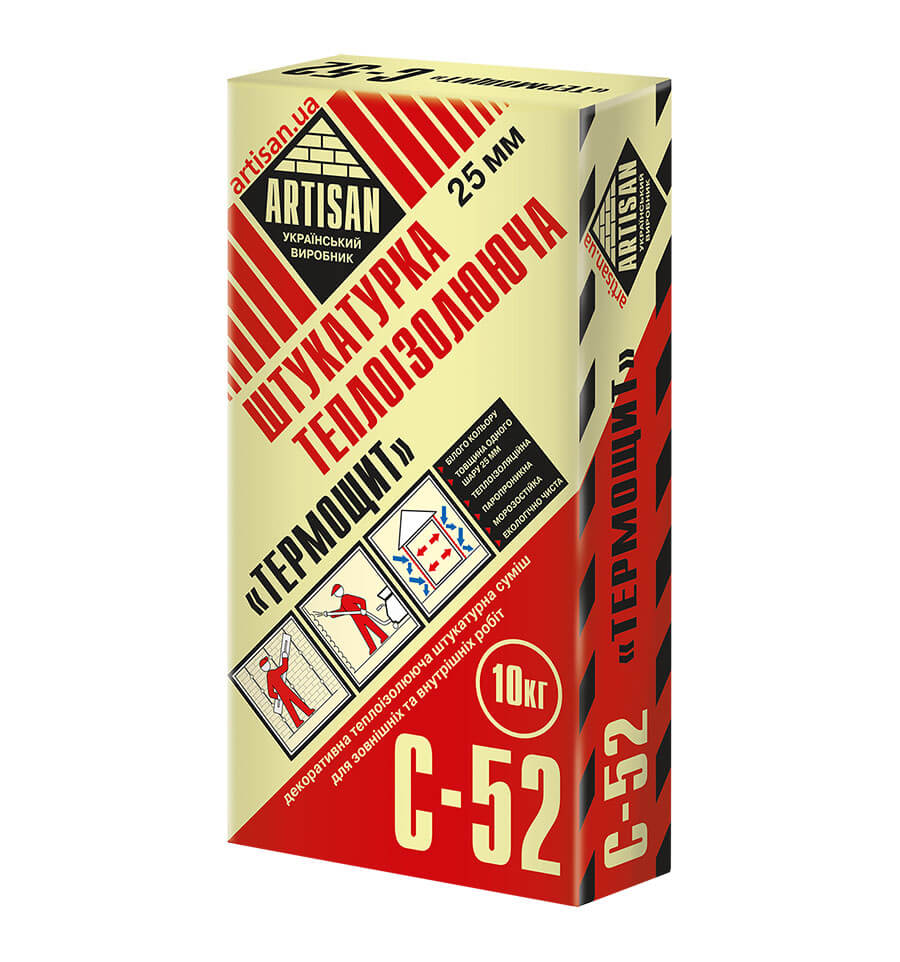

DECORATIVE HEAT-INSULATING PLASTERING MIXTURE FOR EXTERNAL AND INTERNAL WORKS C-52

22.10.2017SELF-LEVELING MIXTURE FOR FLOOR C-42

SELF-LEVELING MIXTURE FOR FLOOR C-42

SELF-LEVELING MIXTURE FOR FLOOR C-42

APPLICATION

The solution is used for manufacturing self-leveling floors (interlayers) on almost any pre-prepared basis in residential and public buildings. The thickness of the layer is 5-20 mm. Pouring into one layer. The ready-made screed meets all the requirements for floor interlayers, which can be applied to all types of coatings (parquet, linoleum, carpet coatings, tiles, paint, etc.)

PREPARATION OF THE SURFACE

The most important factor is the preparation of the substrate. The main requirement is that the substrate should be strong and clean (cementitious grounds – at least 28 days). Before applying floors from the base, it is necessary to remove not only coarse dirt, but even dust, preferably with a vacuum cleaner. Large damages, for example, broken parts of the screed or voids should be filled with putty. All the grounds must be primed with primer Artisan No. 7, or Artisan No. 8 super, depending on the requirements for the substrate. Do not wet the surface of the substrate.

PERFORMANCE OF WORK

The mixture is mixed with water with a low-speed stirrer until a homogeneous mass without lumps is obtained. Wait 5 minutes and mix again. Then pour the solution onto a prepared base and distribute it with a roller, a hard broom, a rubber straps and similar tools. It is recommended to roll the surface of the poured layer with a spiked roller to remove air lock. You can use a piston or auger pump to feed the solution. In the event of a break in operation for more than 20 minutes, the machine should be cleaned with water. The hardened solution can only be removed mechanically.

NOTE!

Excess water reduces the mechanical strength of the solution and leads to delamination. After 36 hours on the floor you can walk. It is possible to apply various coatings to the floor surface in 7-28 days, taking into account the requirements of the state building norms B.2.6-22-2001. The most effective result is achieved at t + 20 ° C and 60% relative humidity. In other conditions, the operating parameters of the mixture may vary. The manufacturer is not responsible for the incorrect use of the material, nor for application of it for purposes and conditions not provided for by the instruction.

SAFETY PRECAUTIONS

The mixture contains cement, which when combined with water forms alkali. It is necessary to prevent the hitting impregnation on the skin and mucous membranes. All work should be carried out in goggles, rubber gloves and protective clothing. Provide fresh air. In case of contact with skin or eyes, rinse thoroughly with water and if necessary, consult a doctor.

EXPIRATION DATE

In dry conditions and hermetic packaging the period of storage is at least 12 months from the date of manufacture.

PACKAGING

The dry mix is packaged in bags of 25 kg.

TECHNICAL CHARACTERISTICS

Composition: mixture of cement with mineral fillers and special additives

Quantity of water for solution preparation, l / kg : 0,22-0,24

Proportion of batch, l / kg : 5,0-6,0/25

Time of use, min, not less than: 20 min

Substrate temperature, ° С: +10 to +25

Compressive strength, MPa, not less than: 15.0

Ready for use: after 7-28 days

Consumption, kg / m2 / mm: around 1.6

LAYER THICKNESS 5 – 20 mm

CONVENIENT IN APPLICATION

PERSISTENT TO THE CONCENTRATED LOAD

HIGH STRENGTH

PERFECTLY SMOOTH SURFACE

DOES NOT BURN

ECOLOGICALLY CLEAN

Mixture “Artisan” Ц.2.ПР1

ДСТУ БВ.2.7-126:2011

Hygienic conclusion of the Ministry of Health of Ukraine.

You must be logged in to post a review.

Reviews

There are no reviews yet.