Adhesive mixture for internal works C-9

16.07.2017

Adhesive mixture universal C-11

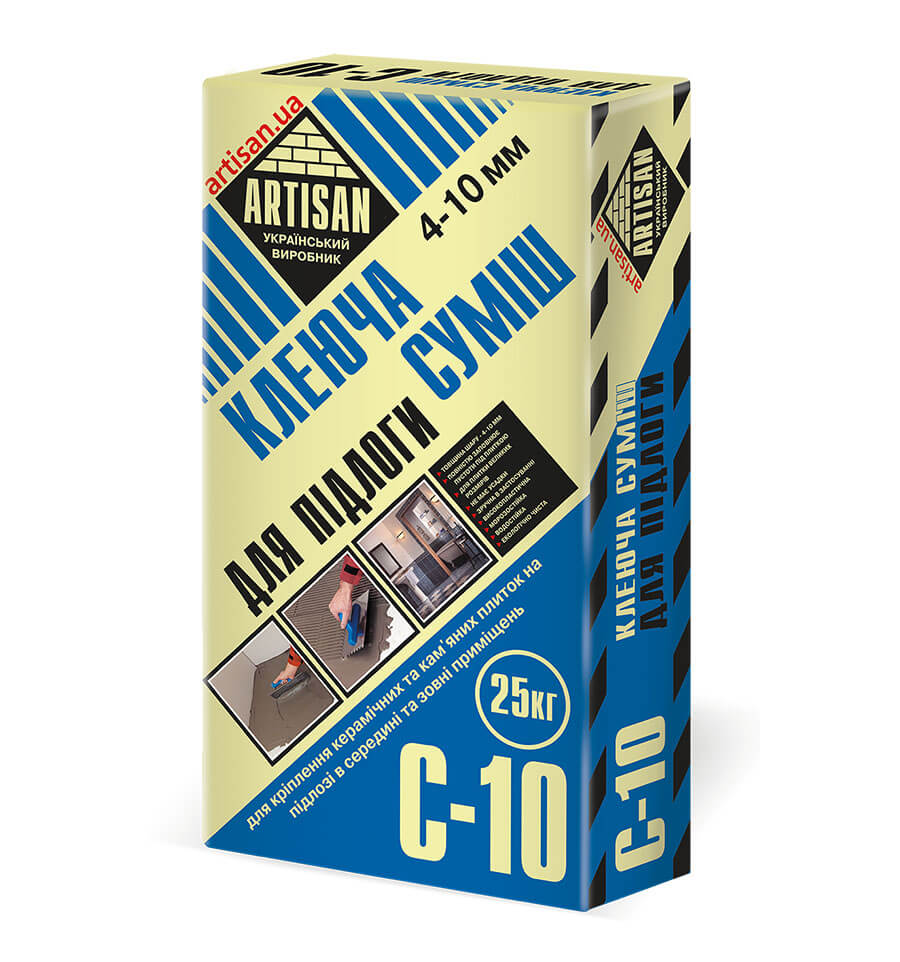

16.07.2017Adhesive mixture for floor C-10

Adhesive mixture for floor C-10 – for fixing ceramic or stone tiles on the floor inside and outside buildings

APPLICATION

The mixture is used for gluing ceramic or stone floor tiles on concrete, monolithic cement floors inside or outside buildings. Also can be used on old ceramic surfaces. A specific feature of the mixture is its increased ductility and fluidity in comparison with standard adhesive solutions, which makes it possible to maximize the filling of voids under large floor tiles. Due to the high plasticity, it is not necessary to use leveling solutions for ceramic laying.

PREPARATION OF THE SURFACE

The substrate should be smooth, dry, durable, free from grease, old paints and other materials that reduce adhesion. The substrate should be treated with primer No. 7 or, if necessary, before application of the mortar mixture – primer No. 8 of the trade mark “Artisan”. Before laying the tiles on the old ceramic surface, the latter must be degreased with caustic soda (1 kg per 10 liters of water) and rinse with clean water.

PERFORMANCE OF WORK

!! Do not wet the tiles.

The dry mixture is mixed manually or mechanically with clean water until a uniform consistency is obtained. Leave the mixture for 3-5 minutes, then mix again. The mortar mixture is applied to the prepared base with the even side of the notched trowel, and then the tooth side is spread over the surface.

At one go, should be used such an amount of mortar to glue the tiles in 20 minutes. The tiles are laid on the mortar and easily pressed against the base. After 48 hours, the surface is ready for technological displacement, you can fill the seams with a fugue.

When carrying out the construction work, it is necessary to be guided by the current building norms and rules. The manufacturer is not responsible for the misuse of the material, nor for its use for purposes and conditions.

SAFETY PRECAUTIONS

The mixture contains cement, which when combined with water forms alkali. It is necessary to prevent the hitting impregnation on the skin and mucous membranes. All work should be carried out in goggles, rubber gloves and protective clothing. Provide fresh air. In case of contact with skin or eyes, rinse thoroughly with water and if necessary, consult a doctor.

EXPIRATION DATE

In dry conditions and hermetic packaging the period of storage is at least 12 months from the date of manufacture.

PACKAGING

The dry mix is packaged in bags of 25 kg.

TECHNICAL CHARACTERISTICS

Composition: a mixture of white cement with mineral fillers and special additives

Quantity of water for solution preparation, l / kg : 0,22-0,24

Time of use, min, not less than: 60

Open time, min, not less than: 20

Correction time, min, not less than: 10

Strength of adhesion to the base, MPa, not less than: 0,8

Temperature of use, ° С: from +10 to +30

Maximum layer thickness, mm: 10

Consumption, kg / m2 / mm: 1,5

LAYER THICKNESS 2-10 mm

COMPLETELY FILLS THE VOID UNDER THE TILE

FOR LARGE TILES

DO NOT HAVE SHRINKAGE

EASY TO USE

HIGHLY PLASTIC

FROST-RESISTANT

WATERPROOF

ENVIRONMENTALLY FRIENDLY

Mixture “Artisan” C.1.RSH1

DSTU B В.2.7-126: 2011

Hygienic conclusion of the Ministry of Health of Ukraine

You must be logged in to post a review.

Reviews

There are no reviews yet.