Mineral plaster С 30 + Perlit

24.09.2017

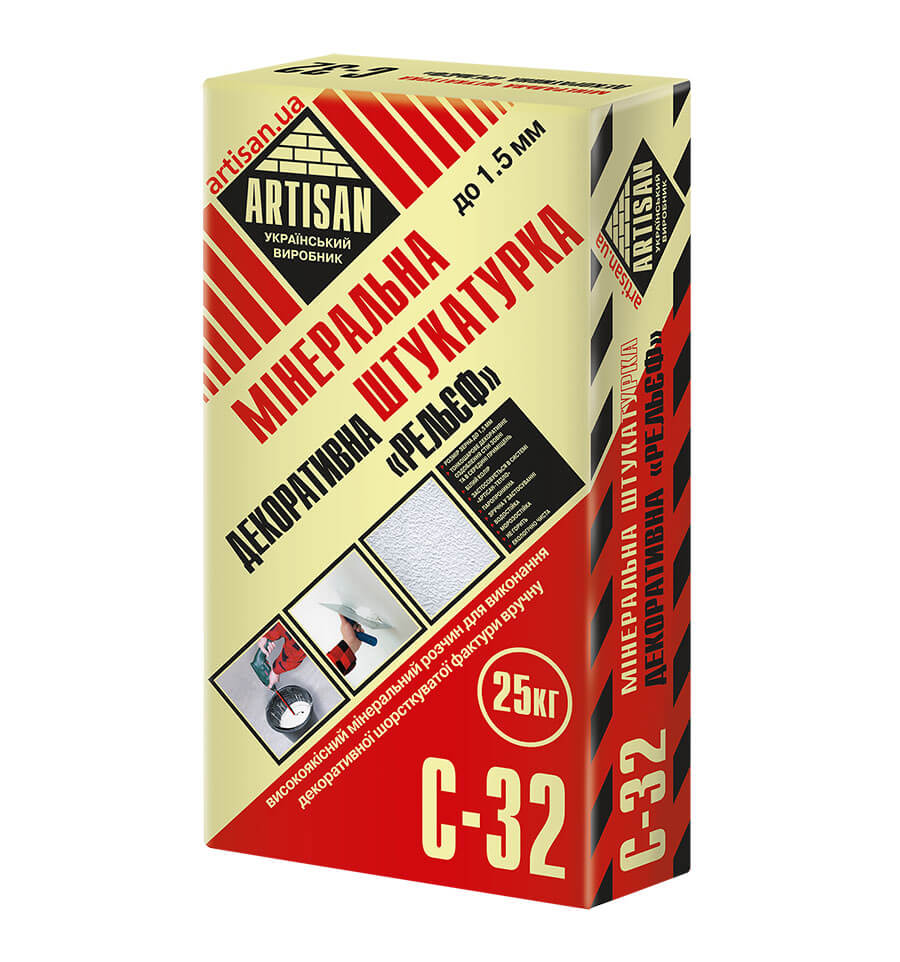

Mineral plaster «Relief» С 32

24.09.2017Smooth white mineral plaster С 31

Smooth white mineral plaster С 31 – thin polymer-cement smooth white plaster (Layer thickness up to 3 mm)

Smooth white mineral plaster С 31 – thin polymer-cement smooth white plaster (Layer thickness up to 3 mm)

APPLICATION

Putty is destined to level the surface of walls with a thin layer of 1-3 mm inside and outside the premises and fill small defects on concrete, cement-lime, cement-sand substrates, on walls and ceilings indoors. The putty should not be used for leveling and repairing foundations of lightweight concrete.

PREPARATION OF THE SURFACE

The preparation of the surface is carried out in accordance with DBN B. 2.6-22-2001 and SNIP 3.04.01-87. The substrate must be dry and strong, without visible damage. The surface should be cleaned of various kinds of contaminants and substances that reduce the adhesion of putty to the substrate (fats, lubricating oils, bituminous mastics, fragile paint and varnish, etc.). Large cracks and irregularities on the base should be filled with the repair mixture, not less than three days before the final leveling of the surface with putty. The bases should be treated with the primer No. 7 TM “Artisan” followed by drying for 4-6 hours. A strongly absorbent substrate should be primed twice.

PERFORMANCE OF WORK

To prepare the Artisan C-31 mortar mixture, take a measured amount of pure cold water (from +15 to +20 ° C). The dry mixture is gradually added to the water with stirring, making it possible to obtain a homogeneous mass without lumps. Stirring is performed with a mixer or a drill with a nozzle. The speed of rotation of the mixer should be 400-600 rpm, then the technological pause is maintained for 5 minutes to ripen the mixture, and mixed again. The mortar mixture is applied to the prepared substrate with the help of special tools and evenly distributed over the surface. It is possible to give the surface a different texture. During the drying and setting of the mortar, it must be protected from direct sunlight, the effects of negative temperatures and precipitation. The aligned surface can be painted and wallpapered, not earlier than 7 days after the puttying. After finishing work, tools, agitator and other containers should be cleaned and rinsed with water, not allowing the mixture to freeze on tools. Hardened putty can be removed only mechanically.

NOTE! Excess water reduces the strength of the solution and can lead to delamination of the solution mixture. Work should be performed at a temperature of +10 ° C to + 30 ° C. Specifications are maintained under normal conditions (temperature 20 ° C and relative humidity 60%). The manufacturer is not liable for improper use of the material, nor for its use for purposes and conditions not provided for by the instruction.

SAFETY PRECAUTIONS

The mixture contains cement, which, when mixed with water, forms an alkali. Work should be in rubber gloves. If the solution gets into the skin or eyes, rinse them with plenty of water, if necessary, consult a doctor.

EXPIRATION DATE

In dry conditions and hermetic packaging the period of storage is at least 12 months from the date of manufacture.

PACKAGING

The dry mix is packaged in bags of 5 and 20 kg.

TECHNICAL CHARACTERISTICS

Composition: Mixture of cement with mineral fillers and special additives

Color: white

Amount of water for batching, l / kg: 0,38-0,45

Application temperature, ° С: from +10 to +30

Layer thickness, mm: 1,0- 3,0

Adhesion to the substrate, MPa, no less than: 0,3

Compressive strength after 28 days, MPa, not less than: 7

Solution flow rate, kg / m2 / mm: 1,2-1,25

Time of using the mortar mixture, minutes : 60

Frost resistance, cycles, not less than: 75

HIGH ADHESION

PLASTIC AND CONVENIENT IN APPLICATION

WHITE PERFECT SMOOTH SURFACE

HYDROPHOBIC

FROST-RESISTANT

ENVIRONMENTALLY PURE

Mixture “Artisan” Ц.1.ШЦ1

ДСТУ БВ.2.7-126:2011

Hygienic conclusion of the Ministry of Health of Ukraine.

You must be logged in to post a review.

Reviews

There are no reviews yet.